Aromatics Technology

Chevron Phillips Chemical’s Aromax® Technology is the premier on-purpose benzene production technology. This technology, paired with the appropriate feedstock, provides a superior ability to convert light hydrocarbons to aromatics and hydrogen. It is best suited to upgrade low-value feedstocks and/or for addressing a hydrogen (H2) shortage.

Process

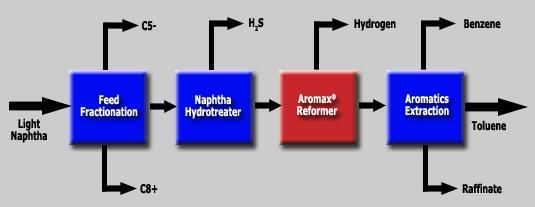

The Aromax® Process selectively converts light paraffins and naphthenes to hydrogen and aromatic products utilizing conventional fixed-bed reforming equipment. The following are fast facts about the Aromax® Process:

- First reforming process based on a zeolitic catalyst

- Best suited for converting C6–C8 hydrocarbons

- Exceptional selectivity for converting C6 and C7 paraffins and naphthenes to benzene, toluene and hydrogen

- Process includes a high-efficiency sulfur control system to eliminate catalyst poisoning by sulfur

- Toluene extraction may or may not be required

- Proprietary catalyst technology

Advantages

Chevron Phillips Chemical’s Aromax® Technology is the premier on-purpose benzene production technology.

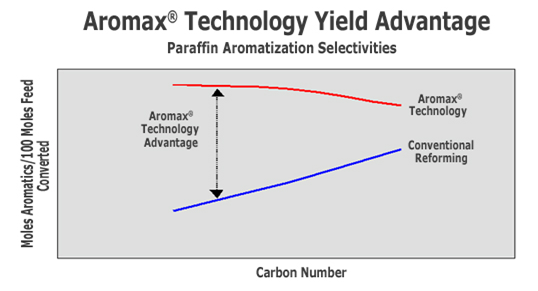

- High yield of benzene, toluene and hydrogen from C6/C7 naphtha

- Enables the use of lower-priced paraffinic naphtha

- Sulfur and carburization control

- 16 years of commercial experience

- Proprietary sulfur and carburization control technology

Licensees

We engage in a limited and highly selective licensing strategy for the Aromax® Technology. The key drivers behind licensing the proprietary technology include:

- Geographic fit

- Feedstock availability/suitability

- Discounted product offtake or equity position by Chevron Phillips Chemical

Technical Service

By licensing our technology, licensees have direct access to our technical resources around the globe. This relationship enables licensees to consult with top researchers and engineers to assist in:

- Catalytic development and improvements

- Developing improved process technologies

- Exploring lower cost routes for manufacturing

Our technology package typically includes:

- A kickoff premises meeting

- An orientation meeting

- Technology manuals

- Laboratory analysis manuals

- A process design package

- Review of process design package with licensee

- Technical assistance during mechanical design and construction of plant

- Review of mechanical flow sheets

- Hazop assistance

- Training of licensee operating and laboratory personnel

- Plant inspection

- Plant startup assistance

We continue to evaluate new licensees and partners on a selective basis. Strategic licensing decisions are made based on geographic and company specific information.