Company History

Chevron Phillips Chemical was established in July 2000 as a joint venture between Chevron U.S.A. Inc. and Phillips 66 Company, combining the chemicals operations of both owner companies.

- Home

- Who We Are

- Company History

1951

Two research chemists, Paul Hogan and Robert Banks, discover high-density polyethylene (HDPE).

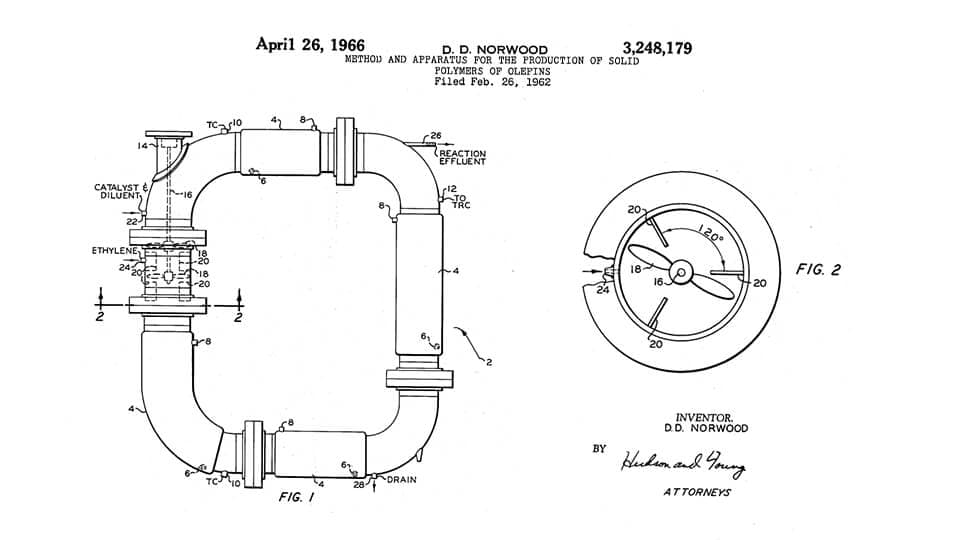

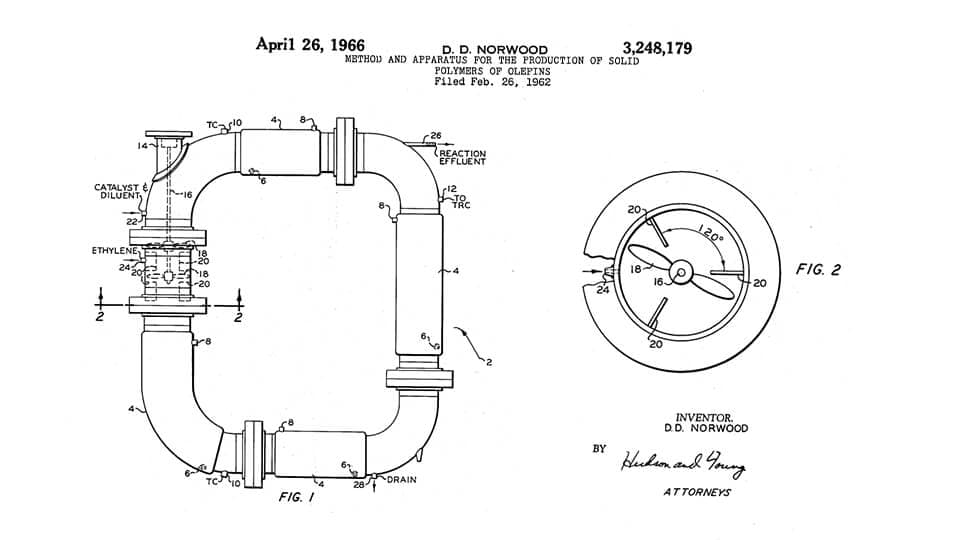

1961

Phillips Petroleum develops the loop slurry process for manufacturing HDPE.

1992

Chevron Research and Technology Company starts up the first commercial Aromax® Technology unit.

2000

Chevron Phillips Chemical is founded as a joint venture between Chevron U.S.A. Inc. and Phillips 66 Company.

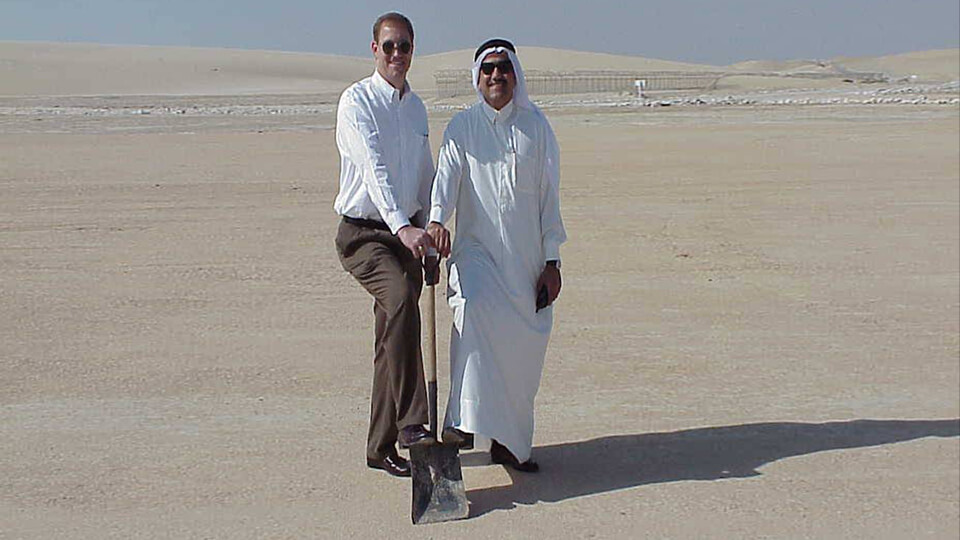

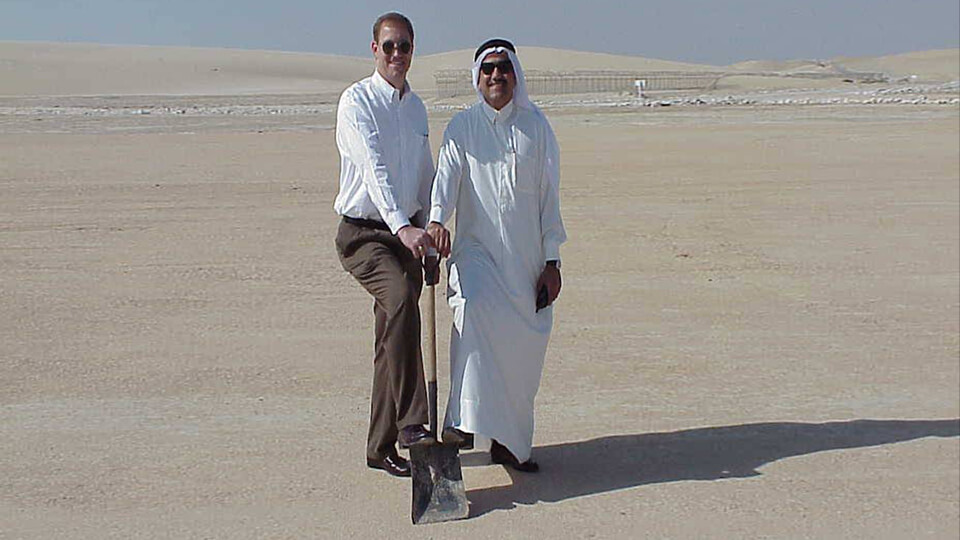

2001

Chevron Phillips Chemical and Qatar Petroleum found the Q-Chem joint venture.

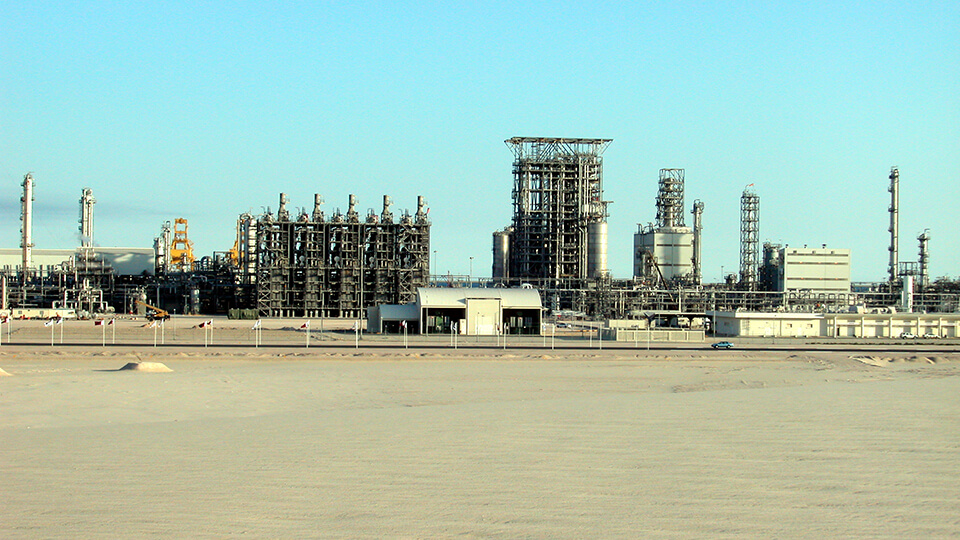

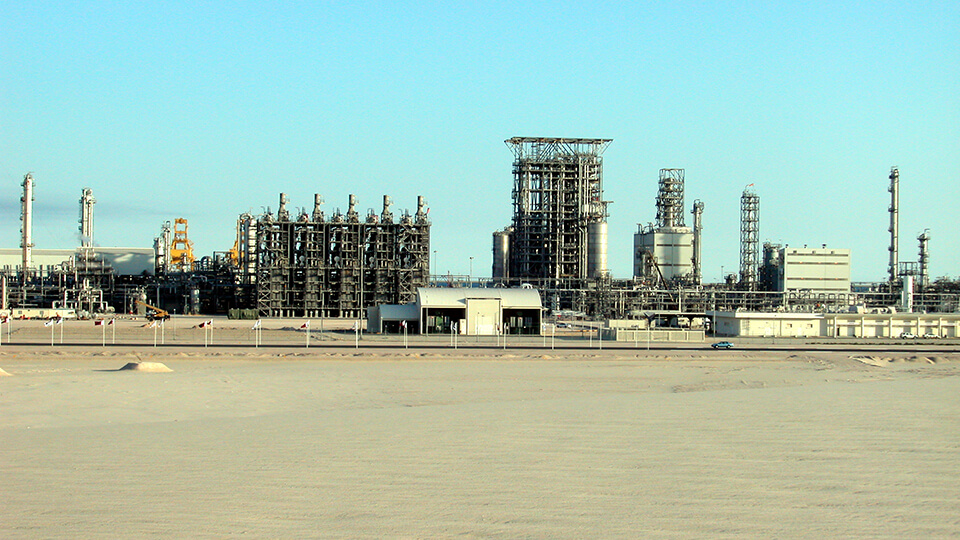

2003

Q-Chem inaugurates its petrochemical complex in Mesaieed, Qatar.

2010

Chevron Phillips Chemical and Ras Laffan Olefins Company Limited (RLOC) start up the Q-Chem II facility in Qatar.

2011

Chevron Phillips Chemical acquires the PAO plant in Beringen, Belgium.

2012

Saudi Polymers Company petrochemical complex in Jubail, Saudi Arabia, begins commercial production.

2014

Chevron Phillips Chemical begins production of 1-Hexene at its Cedar Bayou plant in Baytown, Texas.

2017

The polyethylene unit begins operations at the U.S. Gulf Coast Petrochemicals Project in Old Ocean, Texas.

2018

The ethane cracker begins operations at the U.S. Gulf Coast Petrochemicals Project in Baytown, Texas.

1951

1961

1992

2000

2001

2003

2010

2011

2012

2014

2017

2018

Learn more about our vision, mission and values.

What We Believe

Find out how we support our neighbors and communities.

Community Involvement