Grease is a solid to semi-fluid lubricant, typically used for “difficult to service” equipment such as bearings or suspension systems. When combined with “difficult operating conditions” — including extreme temperatures, high loads, or extended operations — a high-quality base oil may be necessary.

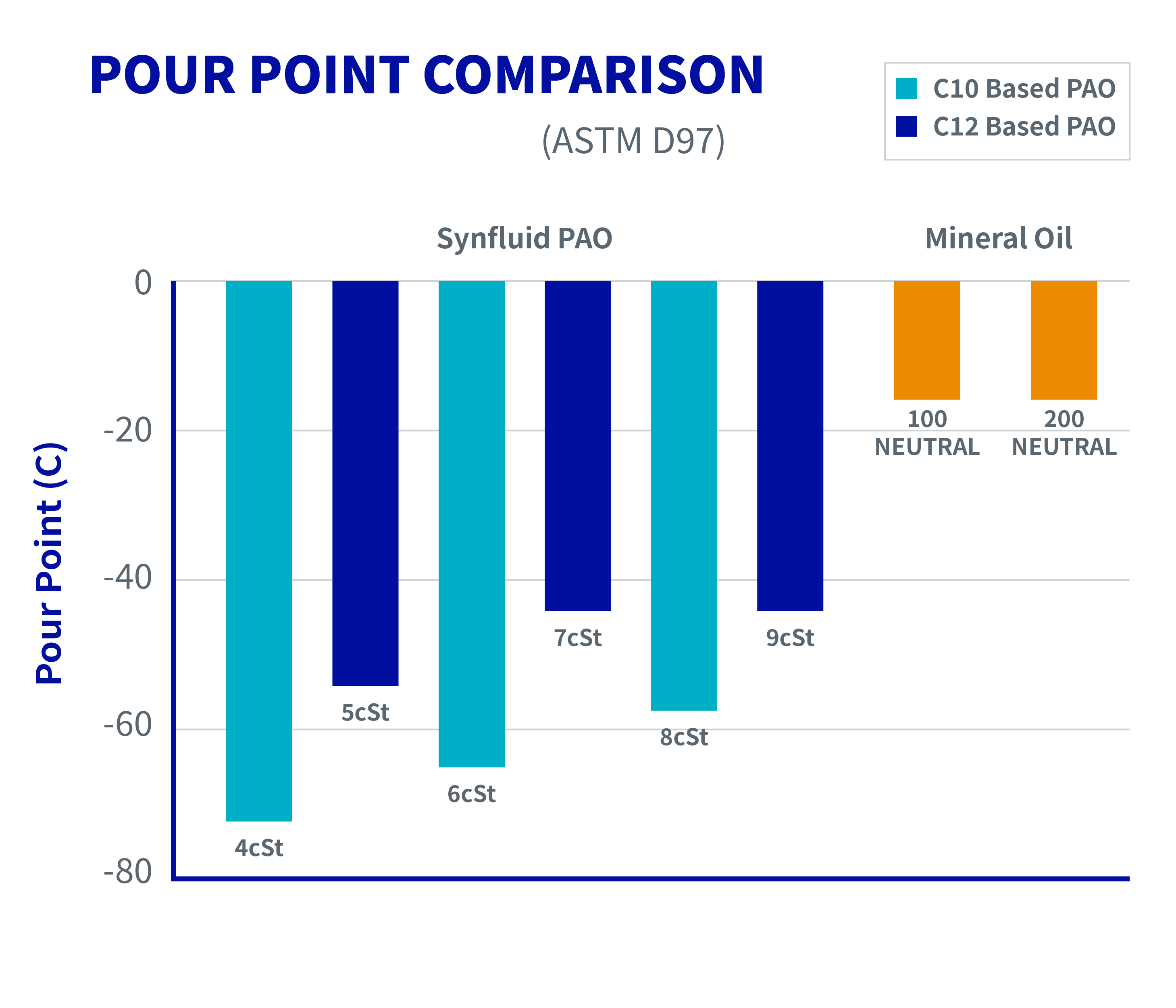

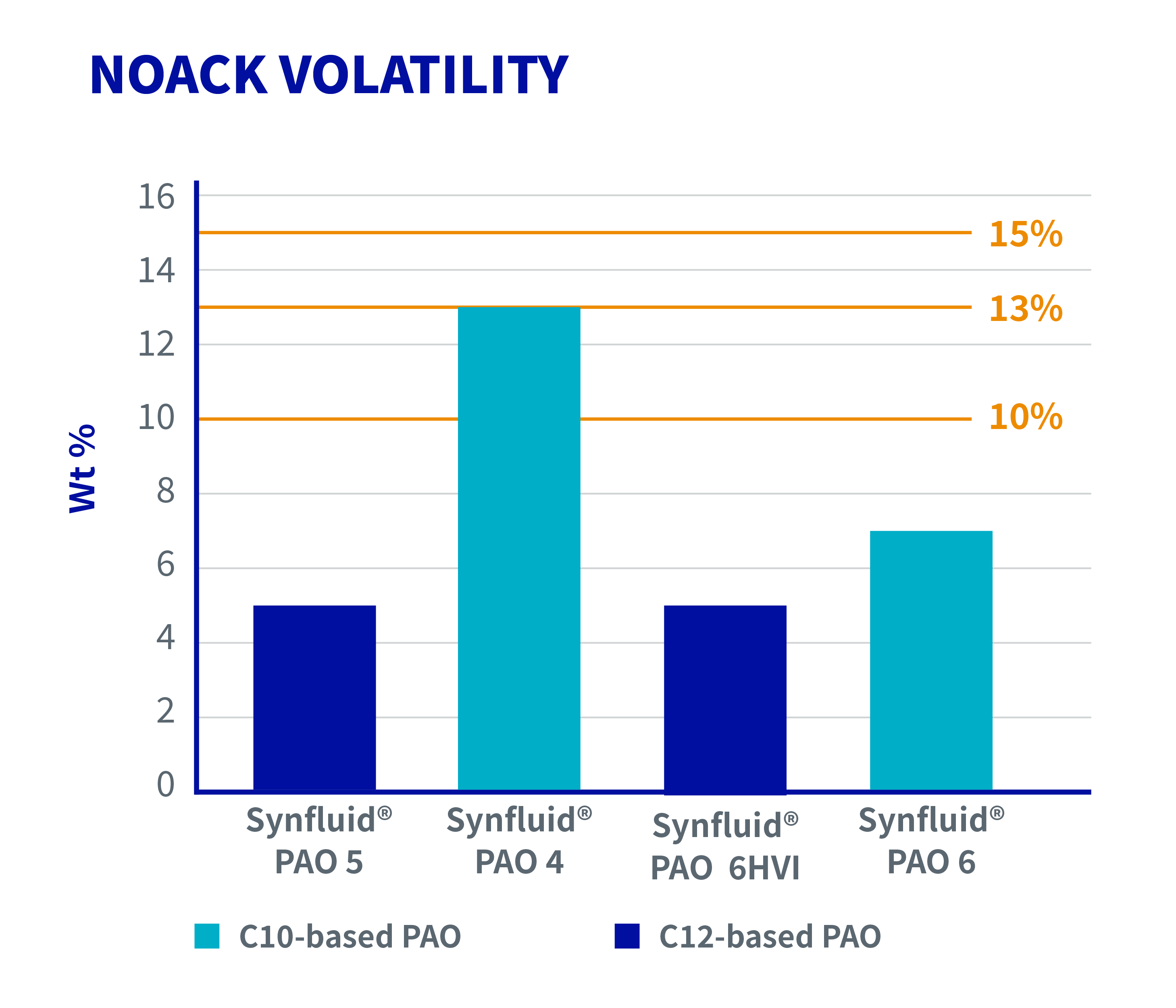

Low-temperature fluidity and high-temperature thermal and oxidative stability are key factors when choosing a PAO. This is especially true when considering the entire operating temperature range, including startup conditions.

The qualitative chart below describes the impact of each grease component on certain performance characteristics:

| | PAO Base Oil | Additive | Thickener |

|---|

| Thermal Stability | + | | + |

| Volatility | ++ | | |

| Oxidative Stability | + | + | |

| Low Temperature Flow | + | | + |

| Solvency | + | | |

| NLGI Grade | | | ++ |

| Fuel Economy | + | | + |

| Antiwear | | ++ | |

| Water Resistance | + | | + |

Clearly, the base oil dominates some grease properties, while the additives or thickener drive others. One example is the advantage PAO has over mineral oil in the area of high-temperature stability. PAO-based greases are typically used at temperatures over 100 °C because of thermal and oxidative concerns. Each 10 °C temperature rise can reduce oxidative stability by half. Therefore, at high temperatures, it is advantageous to utilize a more stable base oil — specifically, Synfluid® PAO.